Introduction of magnetic force

To understand how magnetic filters work, it’s helpful to have a basic understanding of magnetic forces. This will give you insight into the nature of magnetic forces and their usefulness.

Magnetic forces occur between two magnetic objects and can be either attractive or repulsive, depending on the alignment of their magnetic poles.

If two magnetic objects have the same poles, such as two magnets with their north poles facing each other, they will repel each other. On the other hand, if two magnetic objects have opposite poles, such as a north pole and a south pole, they will attract each other. To understand how magnetic filters work, it’s helpful to have a basic understanding of magnetic forces. This will give you insight into the nature of magnetic forces and their usefulness. Magnetic forces occur between two magnetic objects and can be either attractive or repulsive, depending on the alignment of their magnetic poles. If two magnetic objects have the same poles, such as two magnets with their north poles facing each other, they will repel each other. On the other hand, if two magnetic objects have opposite poles, such as a north pole and a south pole, they will attract each other.

The magnetic force between two magnetic objects is calculated using the law of magnetic flux, which was formulated by the English physicist James Clerk Maxwell in 1873. According to this law, the magnetic force is equal to the product of two quantities:

The magnetic force is also calculated using Lorentz’s law, formulated by the Dutch physicist Hendrik Antoon Lorentz in 1867. This law states that the magnetic force acting on a moving electric charge in a magnetic field is equal to the product of the following three quantities:

Magnetic force has wide applications in various fields. For example, magnetic force is used to produce magnets, electric motors, generators, and electron microscopes.

Types of magnetic force

Magnetic force is primarily divided into two main types:

Factors affecting magnetic force

Various factors affect the magnetic force. Some of these factors are:

Introduction

Magnetic filters are devices that use a magnetic field to attract and remove metal particles from liquids and gases. They have a wide range of applications in different industries, such as manufacturing, pharmaceuticals, healthcare, food and beverage, and chemicals. Moreover, they are extensively used in major sectors like petrochemicals, refineries, and power plants to enhance product quality, protect electronic or mechanical equipment, and improve safety.

Function

Magnetic filters work by using the magnetic force between ferromagnetic materials including iron, nickel, and cobalt, and the magnetic field created by the filter. As fluid or gas with metallic particles flows through the filter, these particles are drawn to the magnetic components and cling to the filter’s surface.

Types of magnetic filters

Magnetic filters are available in various designs and sizes for different applications. They are classified based on the type of magnetic field.

1. Permanent Magnetic Filters: These filters utilize permanent magnets made of neodymium or samarium-cobalt alloys to create a constant magnetic field. These types of magnets are well-known due to their durability, low maintenance requirements, and ability to operate without an external power source.

2. Electromagnetic Filters: Electromagnetic filters, also known as electric magnets, use an electrically charged wire coil to generate a magnetic field. The strength of the magnetic field can be controlled by adjusting the current passing through the wire coil, providing more precise control over the filtration process.

3. Hybrid Magnetic Filters: Hybrid filters are designed to harness the benefits of both permanent magnetic and electromagnetic filters. They establish a strong magnetic field using permanent magnets and then use electric magnets to finely adjust the magnetic intensity. This unique configuration offers flexibility and adaptability to meet the changing filtration requirements of the filter’s surface.

Additionally, types of magnetic filters are categorized based on the design as follows:

1. Magnetic Separator with Magnetic Plates

Plate magnets are installed on the exterior part of pipes. Plate magnets and drum magnets are used in fluid transfer lines. These systems are always permanent magnets.

2. Magnetic Separator with Suspended Magnets

Suspension magnets are large block magnets that function with or without a tape system (magnets on tape). They are used to attract metal pieces from the flow of materials on a moving conveyor belt. These systems can be either permanent magnets or electromagnets and are highly suitable for recycling and sorting magnetic components and filters. Suspension magnets establish a strong magnetic field using permanent magnets and then use electric current to turn it on and off in the case of electromagnets.

Magnetic separators with a plate or block magnets have a deeply penetrating magnetic field to capture ferromagnetic particles as small as 1 millimeter.

3. Magnetic separators with magnetic rods

Magnetic separators with magnetic rods have a highly powerful magnetic field, but they have less penetration. By placing them in the product flow path, they establish a direct connection with the passing material. Therefore, magnetic rod separators are the best option for capturing small iron contaminants as tiny as 30 micrometers, and even weak magnetic contaminants like stainless steel processed from bulk streams in fillers and pipeline applications.

Magnetic grids, Clean Flow magnets, and magnetic rod filters utilize magnetic rods.

4. Magnetic separators with cylindrical magnets

Cylindrical magnets are commonly found in separators that automatically and directly remove captured metals. Therefore, they are capable of separating or categorizing large amounts of metallic contaminants.

Generally, these types of magnets can be widely used in the following cases:

Recycling and sorting applications:

Applications of magnetic filters

Magnetic filters have a wide range of applications and are used in various industries. Some common applications include:

2. Water Filtration: Magnetic water filters are used to remove iron, rust, and other metal contaminants from water. They are widely used in municipal water treatment systems, industrial water purification processes, and home water filtration systems. [Image of magnetic water filtration filters]

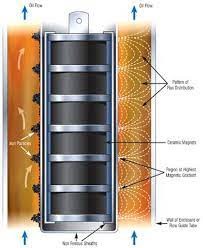

3. Liquid Filtration: Magnetic liquid filters are designed to remove metal particles from different types of liquids, such as oils, lubricants, and coolants. They play a crucial role in industrial applications by safeguarding machinery and prolonging the service life of fluids. Moreover, the use of magnetic filters in various processes also contributes to the increased lifespan of control equipment and machinery used in production lines. Another advantage of these filters is the cost-saving on maintenance and repair of systems. Magnetic separators equipped with magnetic rods have an extremely strong magnetic field, although they have less.

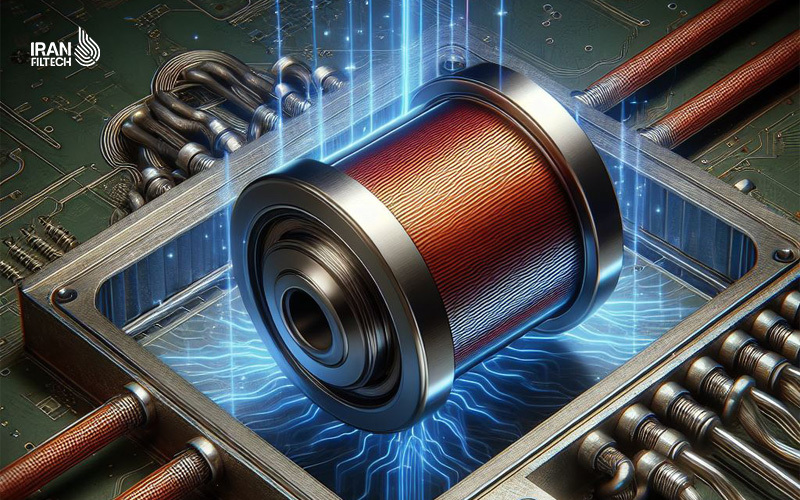

[Image of magnetic liquid filtration filters]

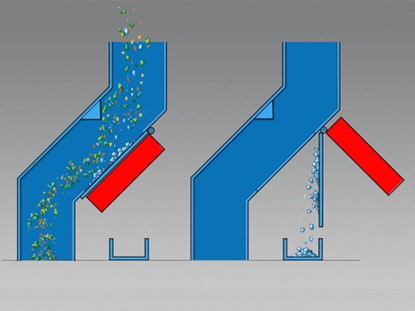

4. Material Separation: Magnetic filters are used to separate metals from waste or other materials for recycling purposes.

[Image of magnetic material separation filters]

Advantages of Magnetic Filters

Magnetic filters offer numerous advantages compared to other filtration methods:

When choosing a magnetic filter, attention to several essential factors is necessary:

Type and size of metal particles: The required magnetic strength and filter design depend on the type and size of metal particles that need to be removed.

Flow rate of fluid or gas: The selection of an appropriate filter size is affected by the flow rate of fluid or gas.

Environmental conditions: It is important to consider environmental factors such as temperature, pressure, and contaminants when selecting a compatible filter.

Budget: The price of magnetic filters varies based on their design, materials, and capabilities. Setting a budget can help to narrow down the options for selection.

Conclusion

Magnetic filters are highly versatile and effective tools for removing metal contaminants from fluids and gases. They contribute to improving the quality of products, protecting equipment, and enhancing overall operational efficiency. These filters can capture even the finest particles, and their selective removal capability and low maintenance requirements make them invaluable in various industrial applications. Proper selection of a magnetic filter can significantly enhance the performance and safety of industrial processes.

Author: Alireza Bahmani

September 2023

Save the post

Save the post Projects: